Coatings at the Core: How Functional Finishes Are Shaping the Future of Manufacturing

In the rapidly evolving world of industrial innovation, progress is not always marked by roaring engines or bright lights. Sometimes, it comes in the form of a thin, almost invisible layer that fundamentally enhances how materials perform, resist wear, and interact with their environments. Once viewed as specialized solutions for niche challenges, functional coatings have now become indispensable across today’s high-performance manufacturing landscape. These advanced finishes do far more than provide protection—they enable transformation.

From extending the lifespan of equipment to driving sustainability initiatives, industrial coatings have become critical components in industries ranging from aerospace to chemical processing. With new technologies emerging and environmental regulations tightening, their role continues to grow in both scope and importance.

A Legacy of Protection and a Future of Precision

Functional coatings have a history that spans more than a century. In the 1800s, materials like natural rubber and oils were used to protect surfaces from environmental damage. The mid-20th century brought a major breakthrough with synthetic coatings such as Teflon® (PTFE), celebrated for its outstanding non-stick and chemical-resistant properties. These innovations redefined how industries addressed friction, contamination, and wear.

By the latter half of the 20th century, materials like Halar® (ECTFE) and Tefzel® (ETFE) expanded these capabilities even further. These coatings offered superior resistance to chemicals and mechanical stress, cementing their place as essential tools for ensuring product durability and performance. In sectors such as automotive and aerospace, where equipment failure is not an option, coatings became critical to success.

Addressing Modern Manufacturing Challenges

Today’s industrial coatings go beyond basic protection. They are integral to improving productivity, enhancing safety, and reducing environmental impact. Advances in nanotechnology have led to coatings with exceptional adhesion, increased wear resistance, and enhanced functionality. At the same time, the industry has shifted toward more environmentally conscious formulations with reduced volatile organic compounds (VOCs), helping manufacturers cut emissions without sacrificing performance.

Customization is now a standard expectation. Manufacturers seek coatings engineered for specific applications, whether it involves heat resistance for electronics, anti-corrosion properties for marine environments, or biocompatibility for medical devices. Providers are responding with tailored solutions that balance chemical compatibility, sustainability, and regulatory compliance.

The Emergence of Smart and Sustainable Coatings

Sustainability is a growing priority across industries, and smart coatings are leading the charge. These advanced materials can adapt to environmental changes such as heat, light, or humidity. Some are designed with self-healing properties, while others help reduce energy use or extend maintenance intervals. Together, they offer cost savings over the product lifecycle and support environmental stewardship.

In sectors with high energy demands, including construction and heavy machinery, coatings that improve insulation or reflect heat are gaining popularity. These innovations enable companies to meet stringent performance and sustainability targets simultaneously.

Looking Forward: Coatings in the Era of Industry 4.0

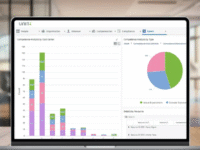

The future of coatings lies in digital integration. IoT-enabled systems and predictive analytics are paving the way for smarter maintenance schedules, helping teams identify exactly when and where a surface requires attention. This approach minimizes waste, maximizes uptime, and streamlines operations.

At the same time, automated application systems are improving the speed, precision, and consistency of coating processes. These advancements are particularly valuable in industries with strict regulatory standards and extreme performance requirements, further solidifying coatings as a strategic element in modern manufacturing.

Final Thoughts

Industrial coatings have evolved far beyond their origins as simple protective barriers. Today, they are essential drivers of innovation, durability, and environmental responsibility. As manufacturing continues to advance, coatings will remain at the forefront, enabling materials to perform better, last longer, and support the demands of a smarter and greener future.

From traditional polymers to next-generationnanocoatings, the path ahead is clear. In an era of high expectations and cutting-edge performance, the value of functional coatings has never been more evident—or more essential.