What Consumer Brands Should Know About Photochemical Etching?

Photochemical etching is a sophisticated metal machining design engineers use to mass manufacture feature-rich metal components and parts. As a consumer, it’s essential to understand what to expect, especially if you are planning to manufacture thin metals. If you are considering photochemical itching, there are many factors that you need to consider, such as the budget, research, and collaboration with other engineers. Further, you must look for reputable professional photochemical etching services to help produce your thin metal. Some people might have heard about photochemical machining, while others might not.

If you are new to the photochemical etching industry, you must know a crucial thing. This article will outline what consumer brands should know about photochemical etching.

What is Photochemical Etching?

Photochemical etching is an alternative method to laser cutting and electric discharge machining. It’s a method to fabricate thin metal parts. The chemicals etchants are used to eliminate unwanted metal sections that are not part of the design, including tiny burrs. Most photochemical etching companies follow a process to provide high-quality products. Some of the techniques include:

Protocol Design/CAD Design

This is where as a client, you present your DXF file or a drawing that the manufacturer will use to create a photo tool. The manufacturer will convert the file into a workable photo tool that technicians will use during every manufacturing process step.

Preparation and Metal Selection

The engineering team will select the best metal to use. They will cut the metal into sheets and clean it to remove all the oxidation, oils, and grease before the etching process begins. The coating helps photo etching on the metal that needs to be removed and shields the metal that needs to remain.

UV Exposure

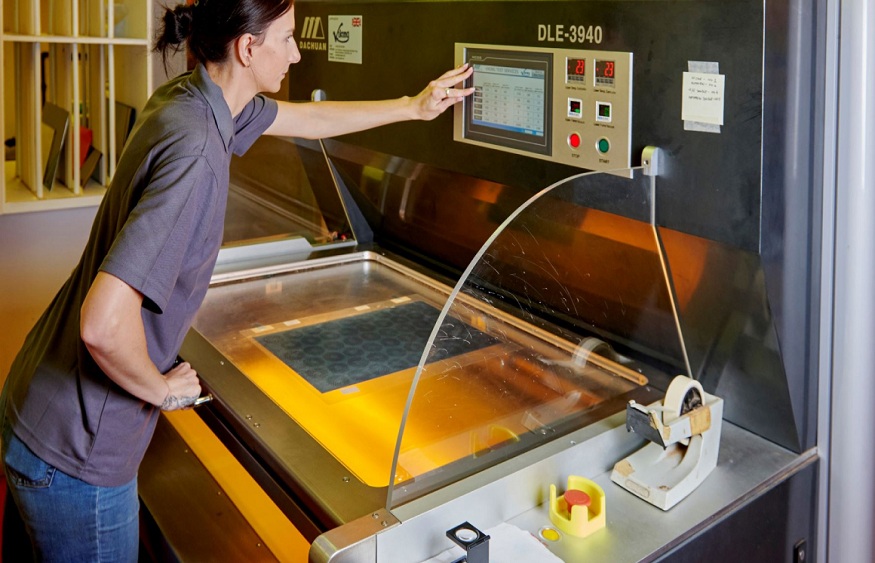

In this process, the metal with the photoresist coating is placed in an exposure unit. It’s created according to the files submitted by the client. It’s exposed to UV light from both sides until it gets polymerized.

Things Consumer Brands Should Know About Photochemical Etching

1. Its Cost Effective

If you are a consumer brand that needs to save some amount when producing thin metal parts, then photochemical etching is your best option. This is because it is easy to create a prototype and modify it. Further, if you are processing metal with the same prototype and thickness, you can process them using the same metal sheet. This will help you reduce the overall time and amount you have used.

2. It helps Ensure Metal Properties are Unaltered

When designing a product, the stress level often conserves most people that the tooling will cause on the metal. However, you can get a low tolerance and high conductivity solution with photochemical itching to prevent deformation.

3. Photochemical Etching Capabilities

If you plan on making multiple thin metal parts that require a wide range of materials, you must consider using photochemical etching capabilities. There are many applications and over 50 metals to incorporate in photochemical etching. Some metals include copper, bronze, beryllium, aluminium alloys, and cold-rolled steel.

Final Words!

Before designing any product, visit the company’s website to see its machine capabilities. Further, hire a reputable, experienced company to do your photochemical etching